Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

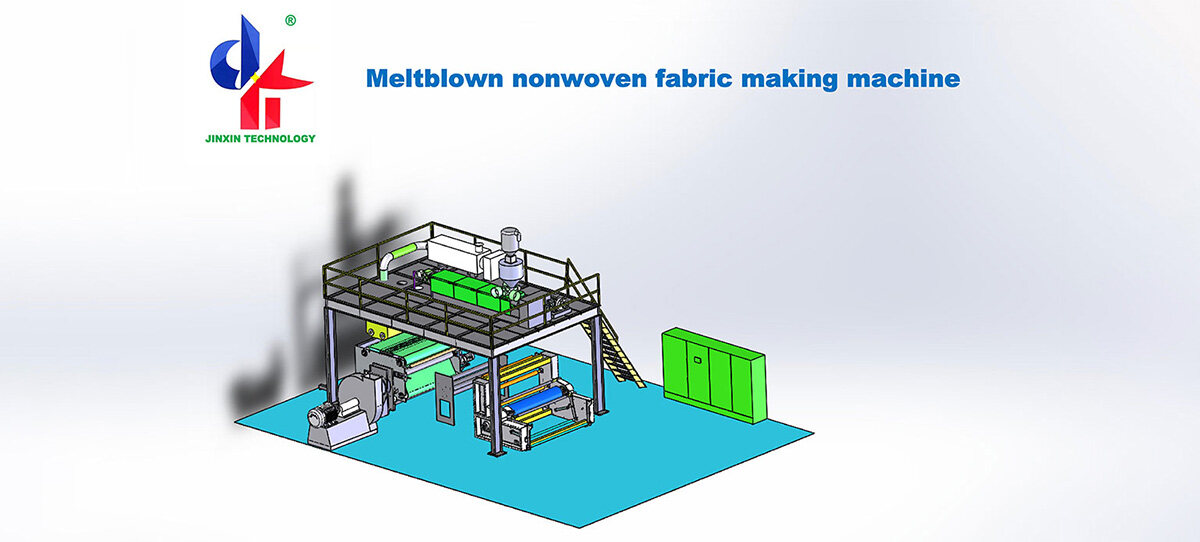

MELTBLOWN модель 3200 мм устройство для нетканого материала

A spinneret, an air plate, a heating element, and a bottom plate make up the melt-blown die assembly's die system. The die head has a direct impact on the uniformity of melt-blown products, however the die head's manufacturing costs are high and its processing precision is quite high.

| Model | JX-Meltblown |

|---|---|

| Product Width | 3200mm |

| Equipment Size | 12*16*8m |

| Mechanical Speed | 80m/min |

| Gram Weight | 20-200g/m2 |

| Daily Output | 2.5-4T/Day |

| Transformer Capacity | ≈630KVA |

| Power Consumption | 3000°-4500°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Meltblown Nonwoven Fabric Production Line Core Component

Die System

The die system of the melt-blown die assembly is composed of a bottom plate, a spinneret, an air plate, and a heating element. The uniformity of melt-blown products is closely related to the die head, but the processing accuracy of the melt-blown die head is very high, and the manufacturing cost of the die head is expensive.

Spinneret

The spinneret is the extrusion die for the production of melt-blown cloth. The spinneret mold is a precision mold. The thickness of the melt-blown cloth depends on the spinneret. The precision of the mold cannot be reached, and the sprayed wire is too thick to achieve the barrier effect.

Spinneret Nozzle

The production of spinneret nozzles is difficult. This kind of nozzle is small in size, and it is necessary to process a complex hole on the small nozzle, which is extremely difficult to process and takes a long time to process. If the processing accuracy is not high, it is easy to cause blockage or affect the melt-blown flow rate and form crystallization, and the final melt-blown cloth produced will not meet the requirements.

Melt Blown Air Heater

The air heater is one of the main equipment in the melt-blown production process because a large amount of high temperature and clean air is required in the melt-blown process. The air heater heats the air delivered by the Roots blower or air compressor to a specified temperature and then delivers it to the melt-blown die. It is not enough to rely on the small holes of the spinneret, and it needs to be stretched by the wind. The air heater is a pressure vessel, and at the same time it must resist the oxidation of high-temperature air, so the material must be stainless steel.

FAQ

Q: What about shipping?

A: We can send the small spare parts by air express for an urgent matter. And the complete production line by sea to save cost. You can either use your own assigned shipping agent or our cooperative forwarder.

Q: Is there any pre-after sale service?

A: Yes, we support our business partners by pre-after sale service. Any cases would be responded to with prompt solutions. We provide training, testing, operation, and maintenance service for a lifetime.