Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

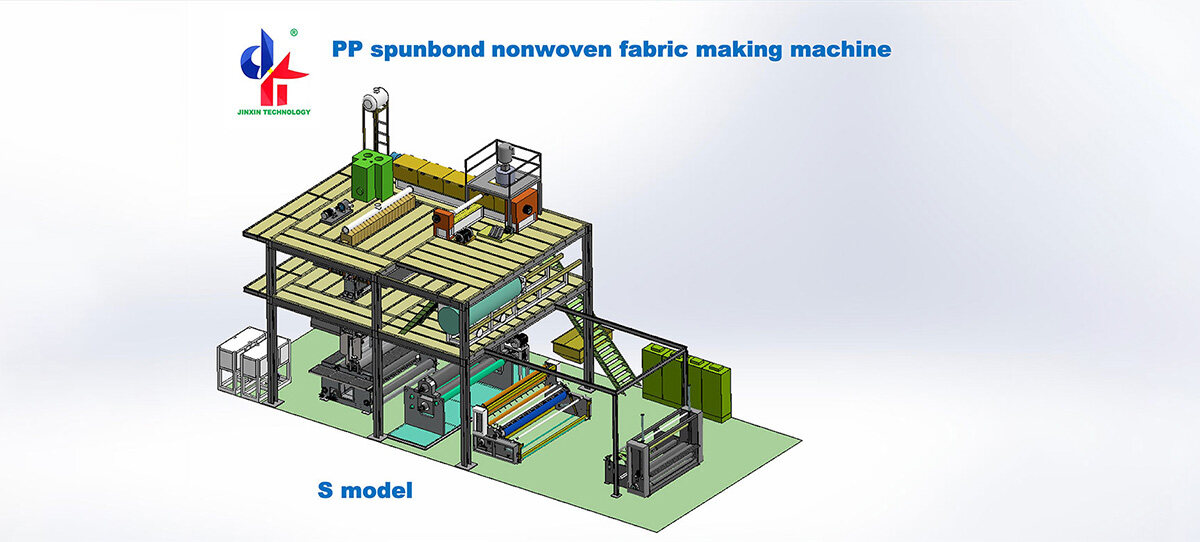

Машина для производства нетканых материалов 1600 мм S

Features of the S non-woven fabric manufacturing machine

1. The usage of needles and thread is avoided by using ultrasonic welding, which eliminates the hassle of having to change needles and threads frequently. Ancient stitching did not have a conversation environment, and it was also capable of doing orderly partial cutting and sealing of textiles. Additionally, sewing serves a decorative purpose. It has a powerful adhesive force, is more sophisticated and attractive, and can produce effects like waterproofing, clear embossing, and double-sided three-dimensional relief. 2. Special steel wheels are processed using ultrasonic technology. The sealed edges have no rough edges or curling marks, are not cracked, do not harm the cloth edges.

| Model | JX-S |

|---|---|

| Product Width | 1600mm |

| Equipment Size | 20*10*12m |

| Mechanical Speed | 150m/min |

| Gram Weight | 10-200g/m2 |

| Daily Output | 4-6T/Day |

| Transformer Capacity | ≈200KVA |

| Power Consumption | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Characteristics of S non-woven fabric making machine

1.Ultrasonic welding is used to avoid the use of needles and thread, which saves the difficulty of changing needles and threads frequently. There is no discussion environment for thread breaking in ancient sewing, and it can also conduct orderly partial cutting and sealing of textiles. At the same time, sewing also plays a decorative role. It has strong adhesive force, can achieve the waterproof effect, clear embossing, double the surface with a three-dimensional relief effect, good working speed and product effect, and is more advanced and beautiful.

2.The use of ultrasonic involves the processing of special steel wheels. The sealed edges are not cracked, do not damage the cloth edges, and have no rough edges and curling signs.

3.Preheating is not required during production and can be operated continuously.

4.It is easy to operate. It is not much different from the skills of sewing machines. Ordinary sewing workers can operate it.

5.Low cost, 5 to 6 times faster than ancient machinery.

Protection and maintenance measures of S non-woven fabric making machine

1.All oil filling points of the equipment shall be regularly added with lubricating oil and engine oil. The real-time replacement of lubricating oil and engine oil can effectively ensure the smooth operation of machinery and reduce the probability of failure.

2.The parts with sealing requirements shall be inspected in real-time every day. If there is any fault or doubt, they shall be repaired or replaced as soon as possible.

3.The protective board of the non-woven fabric making machine shall be inspected every day, and the damaged one shall be replaced in real-time.

4.The guard plate, blade and impeller, directional sleeve, and shot splitting wheel of the shot blasting machine shall be inspected twice every shift. If the above-mentioned one-sided parts are found to be damaged, they shall be replaced in real-time.

5.The electrical system and transmission assembly shall be inspected twice a week to ensure the normal operation of the power system and prevent a short circuit.

6.Conduct regular clean and sanitary inspections, check the environment of parts and components inside the machine, and clean up any foreign matters and pollution found in time to avoid blocking in the machine body and affecting the operation.